YAWEI - Turret Punch - HPI

HPI Series CNC Turret Punch

Special feature:

- Built for maximum flexibility

- Upto 1000 punching cycles per minute

- 36 turret stations standard

- Keeping-touch index tool position (proprietory technology NISSHINBO, Japan)

- Automatic strip-off detector, clamp-sensor

- Rapid loading/unloading of tools

Product description:

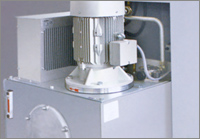

Hydraulic System

H+L hydraulic system completely from Germany, with cooling device of oil temperature, low energy consumption and little volume.

Hardened Die Bush

Turret adopt a sleeve structure, prolonging the service life, the die bush has a higher hardened surface, good antiwearability and easy to change.

CNC System

- Display 10.4 inch, true colour, multi language

- CPU: 223 MHZ/400MHZ

- I/O interface: RS232, 100M Ethernet, USB interface, CF card slot

- RAM: IG/40G

- Good expandability

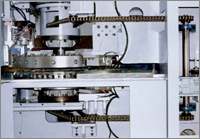

Driving Turret

Compact structure, high precision of driving, reliable and stable.

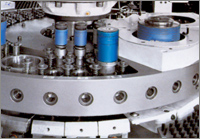

Turret & Index Tools

Thrick turret structure, better guiding and higher precision.

Keeping-touch index tool position, higher precision and efficiency.

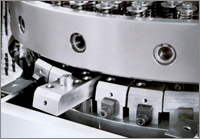

Lower Die Rapid Unloading

Lower die rapid loading and unloading accurately, rapidly, and conveniently

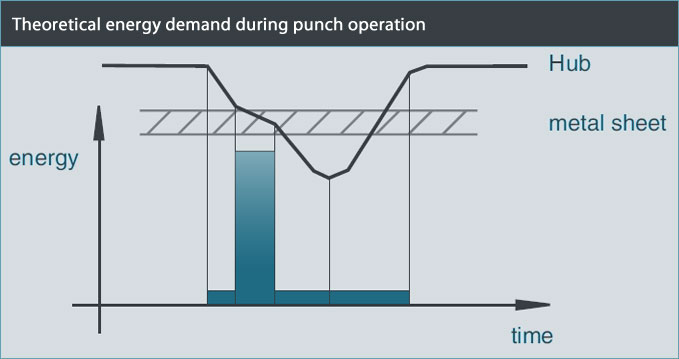

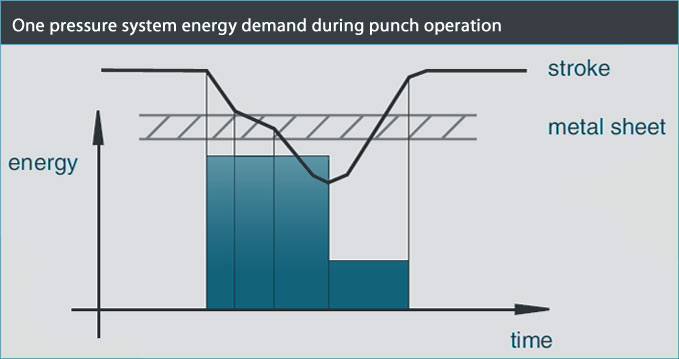

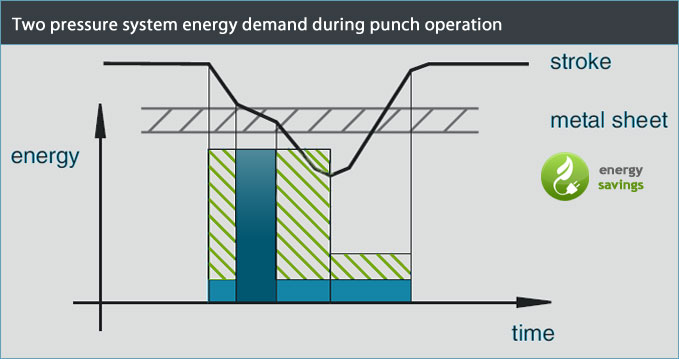

VOITH H&L "GREEN" dual pressure ram control units, working with stepped power, two pressure supply system as well a load dependent switching, guarantees up to 58% reduction of energy cost compared to standard hydraulic systems.

|

Parameter |

Unit |

HPI-3044 |

HPI-3047 |

HPI-3048 |

|

Nominal Presure |

KN |

294 |

294 |

294 |

|

Max sheet dimension |

mm |

1250x2500 |

1250x4000 |

1250x5000 |

|

Carbon steel sheet |

mm |

6.35 |

6.35 |

6.35 |

|

Stainless steel sheet |

mm |

4 |

4 |

4 |

|

Max one-time punching diameter |

mm |

Ø88.9 |

Ø88.9 |

Ø88.9 |

|

Dies |

|

36 |

36 |

36 |

|

Punching cycles per minute |

cpm |

1000 |

1000 |

1000 |

|

Max punching frequency (1mm step 6mm punching stroke) |

cpm |

595 |

595 |

595 |

|

Max sheet speed |

m/min |

102 |

102 |

102 |

|

Air presure |

Mpa |

0.6 |

0.6 |

0.6 |

|

Axes of control |

|

5(X, Y, Z, T, C) |

5(X, Y, Z, T, C) |

5(X, Y, Z, T, C) |

|

Main power |

kW |

21 |

23 |

24 |

|

Punching Accuracy |

mm |

±0.1 |

±0.1 |

±0.1 |

|

Turret speed |

rpm |

30 |

30 |

30 |

|

Overall dimension(LxWxH) |

mm |

5600x2300x2200 |

5600x4000x2200 |

5600x5000x2200 |

|

Weight |

kg |

14000 |

15000 |

16000 |

HPI Series - Standard Accessories

CNC controller is 840D from SIEMENS, Germany

Hydraulic system is a original complete set from H+L, Germany

Standard tool station number: 38LA2(B)

Automatic side-positioning device when locating the sheet

Equipped with brush worktable

Automatic lubricantion system

Automatic strip-off detector, clamp-sensor

Lamp and worktable for replacing tooling

Often-use internal hexagonal key spanner for adjusting tools

It has functions of punching, forming, wheel ribbing function etc.

HPI Series - Optional Accessories

CNC controller change to FANUC Oi-PC, Japan

CNC controller change to Yawei controller(Gogool+Panasonic motors)

CNCKAD (Israel) Software

Air-condition for e-cabinet (600W)

Turret tooling station changed to 26LA2(B)

Turret tooling station changed to 40LA2(2D)

Turret tooling station changed to 38LA2(2D)

Equipped with tooling hoisting device by pneumatic cylinder, replace tooling device and table

Air blow, oil mist function

Programable automatic moveable clamps

Extra standard clamp

Floating clamp by manual

Down-forming function parts

Stainless worktable with steel balls

Leuze light curtain with mirrors around the machine for safety guarding

Extra working table size by 1300*835mm/piece

Mobil hydraulic oil with the machine

_crop_Yawei_TurretPucnh_HPI.jpg)

_crop_Yawei_TurretPucnh_HPH.jpg)

_crop_Yawei_TurretPucnh_HPE.jpg)

_crop_Yawei_TurretPucnh_HIQ.jpg)