YAWEI - Turret Punch - HPE

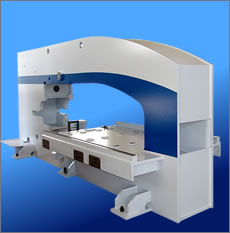

HPE Series CNC Turret Punch

Special function:

- The bridge frame design offers superior rigidity and stability.

- This coupled with highly accurate punching control makes these machines suitable for high speed punching, forming and embossing applications, as well as Wilson wheel type applications such as pinching wheels, slitting wheels and forming operations.

Product description:

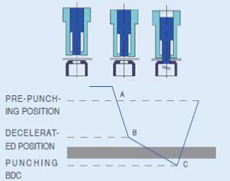

SERVO RAM DESIGN

Ram design uses a single servo motor coupled directly to the crankshaft for highest punching performance and reliability. Simplified design enhances component life and ensures positioning accuracy using a closed loop servo control system.

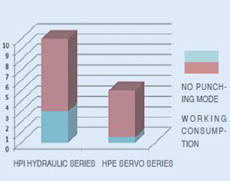

ENERGY EFFICIENCY

Intelligent punching mode calculates punching force,stroke and speed providing maximum performance with reduced energy consumption with near zero energy usage in non punching mode. Additionally, energy generated during “ braking “ mode is recycled reducing overall energy usage.

HIGH SPEED , LOW NOISE

Advanced punching technology provides full control of ram speeds, stroke and forming combined with low noise and energy consumption.

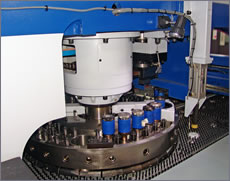

Turret structure

Big depth structure, adopt the parts from Nisshinbo, ensure the precision and wearable function of the turret. To ensure the precision positioning of turret table and tooling, reducer unit imported from Japan.

Frame structure

Welded O-type rigid frame, finite element analysis and design, overall heat treatment for stress relief to meet high-dynamic and high-precision and ensure the performances of the machine and the consistent accuracy provide convenience for maintenance and tool change.

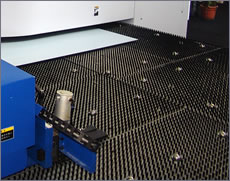

Worktable

Nylon brushes and balls combined table maintains the surface quality of the stainless steel and fine surface materials, keeps the machine running quietly and smoothly. Working portable light and air sprayer provide convenience for maintenance and tool change.

Lower Die Rapid Unloading

Lower die rapid loading and unloading accurately, rapidly and convenient.

Beam and clamps

Adopt the high precision, moved with long-stroke ball screw, linear guide-way guiding, having rapid speed, high moving precision, and long life. High strength prolonged clamp with less dead zone Each clamp has one sensor, once sheet is loosened, punching operation will stop immediately.

Feeding Material and Clamp

Long stroke precision ball screw, four guiding-slots linear guide ensuring excellent lent positioning precision. Adopting high strength floating leverage unit, makes the cylinder clamping more stable and reliable. Equipped with loosening- alarm to ensure safe process.

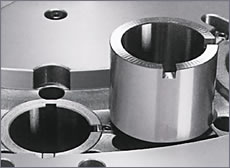

Hardened Die Bush

Turret adopts a sleeve structure, prolonging the working life. The die bush has a hardened surface, good anti-wear properties and easy to change without dismounting the entire turret like other brands..

|

Parameter |

Unit |

HPE-3044 |

HPE-3047 |

HPE-3048 |

|

Nominal Presure |

KN |

294 |

294 |

294 |

|

Max. Processing sheet size |

mm |

1250×2500 |

1250×4000 |

1250×5000 |

|

Max. Punch diameter |

mm |

ø88.9 |

ø88.9 |

ø88.9 |

|

Punching Accuracy |

mm |

±0.1 |

±0.1 |

±0.1 |

|

Ram stroke |

mm |

1500 |

1500 |

1500 |

|

Maximum speed of the plate movement |

m/min |

102 |

102 |

102 |

|

Turret speed |

rpm |

30 |

30 |

30 |

|

Power of feed motor |

kW |

6.1 |

6.1 |

6.1 |

|

Overall dimension(LxWxH) |

mm |

5410x2300x2260 |

5410x4000x2260 |

5410x5000x2260 |

|

Weight |

kg |

14000 |

15000 |

16000 |

HPE Series - Standard Accessories

SIEMENS 840D CNC controller

Electric Servo ram designed by Yawei

Standard tool station : 38LA2(B)

Automatic side-positioning device when lacating the sheet

Moveable pneumatic clampings by manual

Equipped with fixed brush table

Automatic lubrication

Automatic strip-off detector, clamp-sensor

Lamp for changing tooling

It has functions of punching, forming, rib wheel, rolling cutting, rolling pincher and marking etc.

HPE Series - Optional Accessories

CNCKAD (Israel) Software

Air-condition for e-cabinet (600W)

Moveable operating station

Tooling hoisting device and tools for replacing tooling

Optional tool station : 26LA2(2B)

Optional tool station : 40LA2(2D)

Optional tool station : 38LA2(2D)

Extra standard clamp

Programable automatic moveable clamps

Air blow, oil mist system

Down-forming function parts

Stainless worktable with steel balls

_crop_Yawei_TurretPucnh_HPE.jpg)

_crop_Yawei_TurretPucnh_HPI.jpg)

_crop_Yawei_TurretPucnh_HPH.jpg)

_crop_Yawei_TurretPucnh_HIQ.jpg)