YAWEI - Turret Punch - HIQ

HIQ Series CNC Turret Punch

Special function:

Full touch human-machine interface, user-friendly design and powerful CNC system

New industrial design, high-quality production process, de lightful

High end H+L hydraulic system, punching frequency 2,000 times/min

Big tool station turret without frequent change tools

High-powered dual-axis synchronous control unit, more ef ficiently

Keeping-touch auto index, high repositioning accuracy

Rich configuration, meet customer needs from all aspect.

Product description:

Hydraulic System

- H+L hydraullc system from Germany, equip with hydraulic cooling device,low energy consumption,small in size

- Punch frenquency 2000 times/min

- Mainvalve controlled by servo motor,high positioning accuracy

- Precisely control of position, thelower dead point positioning accuracy ±0.03mm

Auto-index

Keeping-touch patent transmission structure without worrying about secondary positioning error and wear. repositioning precision within 0.03mm, better suitable to precision machining, the master drive adopt imported precision worm gear structure, linkage control with T-axis,control system accurately read the real time location for processing, standard equipe with 1B1D auto-index station

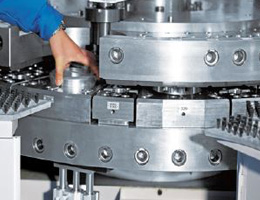

Turret structure

Turret using high strength alloy casting steel, processed through one-time clamp precision machining.strong antioxidant and carrying capacity, Excellent vibration absorption and precision-oriented performance, less tool stuck, strip or other phenomena.and effectively reduce the plate deformation when punching High-density hole Guide bushing with precision machining, significantly increasing the tool life.

lower die rapid unloading

Speicial U-notch, replace tool with no obstruct, easier to use,user-friendly unloading tool devicein big station, reduce operator work intensity.

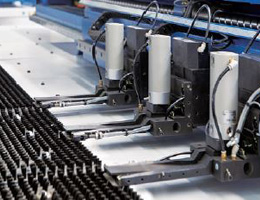

Automatic programable clamp

The program automatlcally adjust clamp to the most suitable position according to the processing sheet metal,without manual adjustment, swing clamp grip finger can be adjusted according to the specification of processing sheet metal to avoid rigid force.

Rapid tool exchange

Humanized design assistance tool exchange dramatically reducing the labor strength, enhance the safety and reduce uncertainty, with the help of tool hositing device you can easily exchange tools upto 10 kilograms, automatic tool hoisting make iieasily to remove the lower die.

|

Parameter |

Unit |

HIQ-3048 |

HIQ-3058 |

|

Nominal Presure |

KN |

294 |

294 |

|

Max. Processing sheet size |

mm |

1250x5000 |

1500x5000 |

|

Max punching frequency (1mm step 6mm punching stroke) |

cpm |

800 |

800 |

|

Max. Punch diameter |

mm |

|

|

|

Punching Accuracy |

mm |

ø88.9 |

ø88.9 |

|

Maximum speed of the plate movement |

m/min |

±0.1 |

±0.1 |

|

Turret speed |

rpm |

102 |

102 |

|

Power of feed motor |

kW |

30 |

30 |

|

Overall dimension(LxWxH) |

mm |

27 |

27 |

|

Weight |

kg |

5410x5000x2200 |

5910x5000x2200 |

_crop_Yawei_TurretPucnh_HIQ.jpg)

_crop_Yawei_TurretPucnh_HPI.jpg)

_crop_Yawei_TurretPucnh_HPH.jpg)

_crop_Yawei_TurretPucnh_HPE.jpg)