HACO FL SERIES FIBER LASER

HACO FL SERIES FIBER LASER

FL 3015 LU, FL 4015 LU, FL 4020 LU

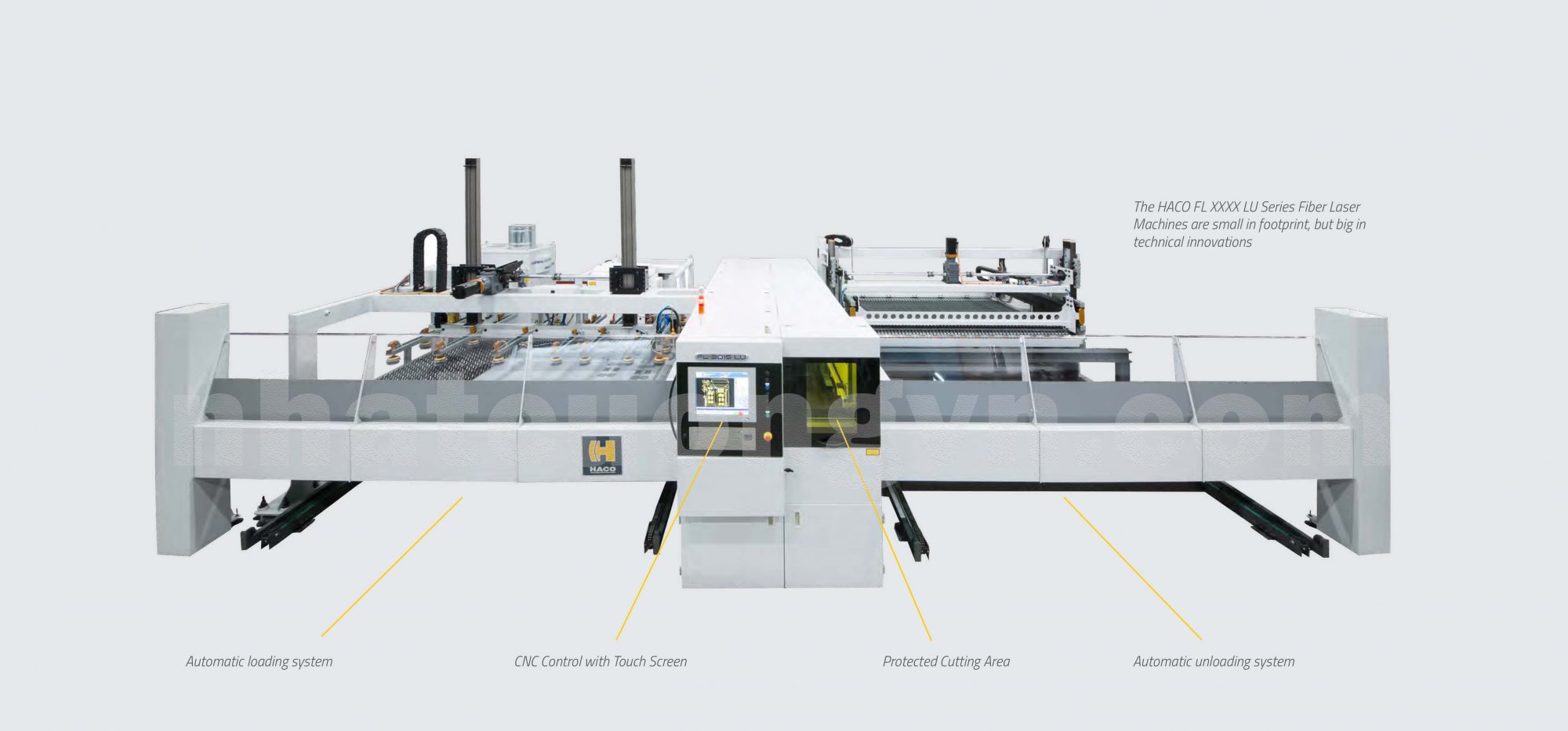

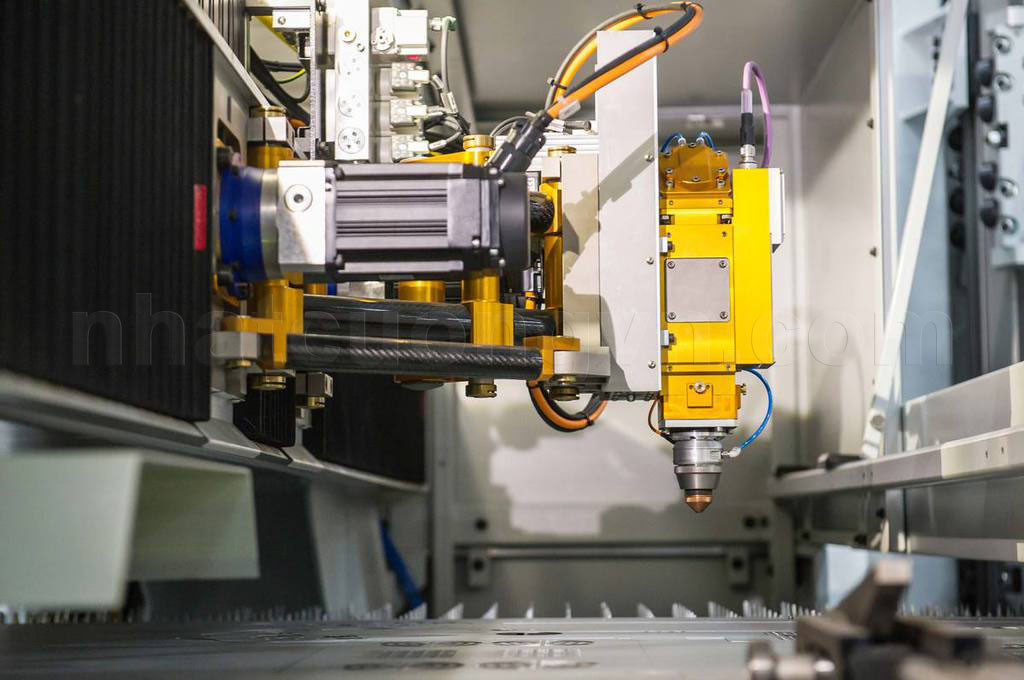

HACO now offers 3 and 4 meter fiber laser cutting machines with 2, 3 and 4 kW laser power together with an integrated loading and unloading system, resulting in a compact, high dynamic laser cutting cell with a footprint of less than 11 by 6 meters, fit for unmanned operation. The FL series features an innovative cutting head, applying ‘Parallel Kinematics Technology’ for high dynamic 5 g cutting processes.

|

STANDARD EQUIPMENT > Application of lightweight carbon technology for fast and precise movements of the laser head |

|

|

FEATURES > Higher cutting speeds (especially for thin materials), lower operating costs |

|

|

FIBER CUTTING HEAD The head is provided with a motorized focal lens which is commanded by the CNC controller. The cutting head is composed of 3 main parts: |

|

|

ROFIN FIBER LASER SOURCE The machine is standard offered with a Rofin FL Series source, featuring a diode pumped YB-fiber laser. The laser is equipped with a direct fiber of 50/100 μm. |

|

ADVANTAGES > High beam quality (*) Laser diodes and fiber have a limited life time but are exchangeable |

|

|

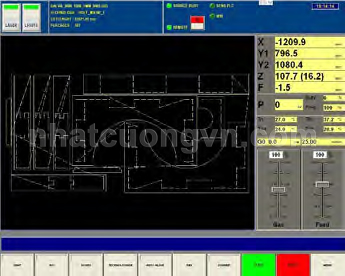

ALC59-T LASER CONTROL WITH TOUCHSCREEN Driven by high-performance, PC-based hardware, the ALC59-T allows very fast processing of data and highly accurate calculation of laser cutting operations. |

|

Features: • 19" color TFT display |

|

|

ROBOLASER USER INTERFACE The highly advanced software "RoboLaser" raises the bar for other Fiber Laser software on the market. |

|

|

|

FL 3015 LU |

FL 4015 LU |

FL 4020 LU |

|

Max. Sheet Dimensions |

3000 mm x 1500 mm |

4000 mm x 1500 mm |

4000 mm x 2000 mm |

|

Machine dimension (including automatic Loading and Unloading system, fiber laser source, chillers, fume extractor and safety fences) |

10.600 mm(L) x 5.500mm (W) x 1.950 mm (H) (*) |

12.600 mm(L) x 5.500mm (W) x 1.950 mm (H) (*) |

12.600 mm(L) x 6.500mm (W) x 1.950 mm (H) (*) |

|

Machine Weight |

+/- 8.500 kg |

+/- 10.200 kg |

+/- 10.800 kg |

|

Positioning accuracy |

+/- 0.1 mm |

+/- 0.1 mm |

+/- 0.1 mm |

|

Programming accuracy |

0.01mm |

0.01mm |

0.01mm |

|

Chip to chip automatic load and unload cycle |

40 sec |

40 sec |

40 sec |

|

Complete automatic load and unload cycle |

50 sec |

50 sec |

50 sec |

|

Electrical consumption working at 20°C with full 3000W laser load, cooling unit and fume extractor included |

40 KVA |

40 KVA |

40 KVA |

|

Voltage |

400V – 3phases (L1,L2,L3, PE) 50Hz +/- 10% |

400V – 3phases (L1,L2,L3, PE) 50Hz +/- 10% |

400V – 3phases (L1,L2,L3, PE) 50Hz +/- 10% |

|

Main switch protection ( 3000W) |

80A |

80A |

80A |

|

Protection in main cabinet (all components) |

63A |

63A |

63A |

|

Required Compressed air |

6 bar – 50Nm³/h |

6 bar – 50Nm³/h |

6 bar – 50Nm³/h |

|

Average compressed air consumption |

6 bar – 15Nm³/h |

6 bar – 15Nm³/h |

6 bar – 15Nm³/h |

_crop_hacolaserfiberfinalweblight-1-1-2.jpg)