Yawei - HGS (K)

Yawei - HGS (K)

|

Structure feature |

|

|

|

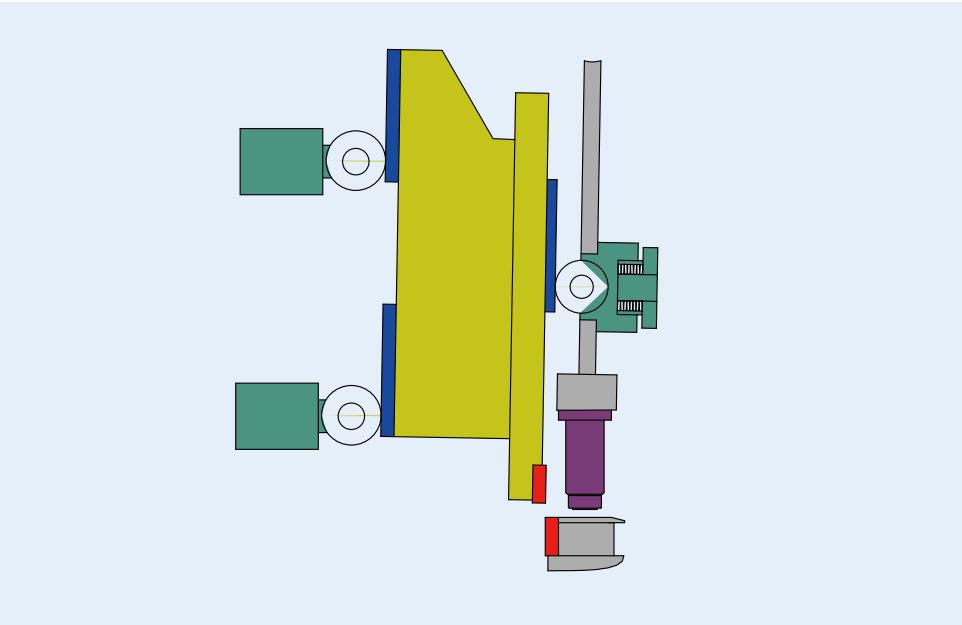

Guide structure |

|

Adopt three wheel break type structure, under the force disc spring, front roller makes the upper beam touch with the two rear rollers all the time, insure the upper beam move up and down stably with go clearance. |

|

|

|

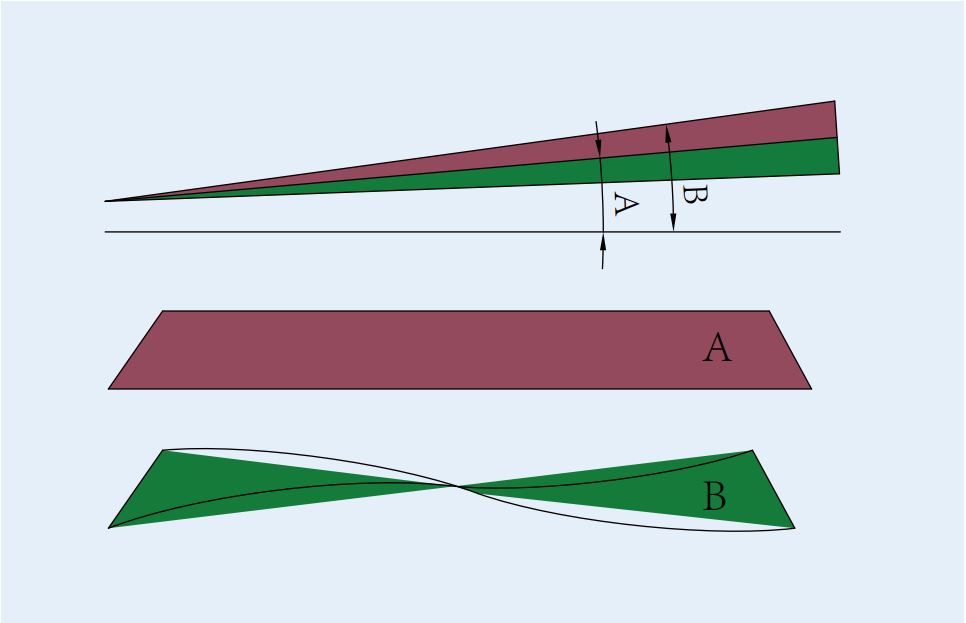

Adjustable cutting angle |

|

Increase the cutting angle, force needed to make cutting is small, workpiece is easy to make deformation; reduce the cutting angle, force needed to make cutting is big, workpiece is flat and cross section is smooth. |

|

|

|

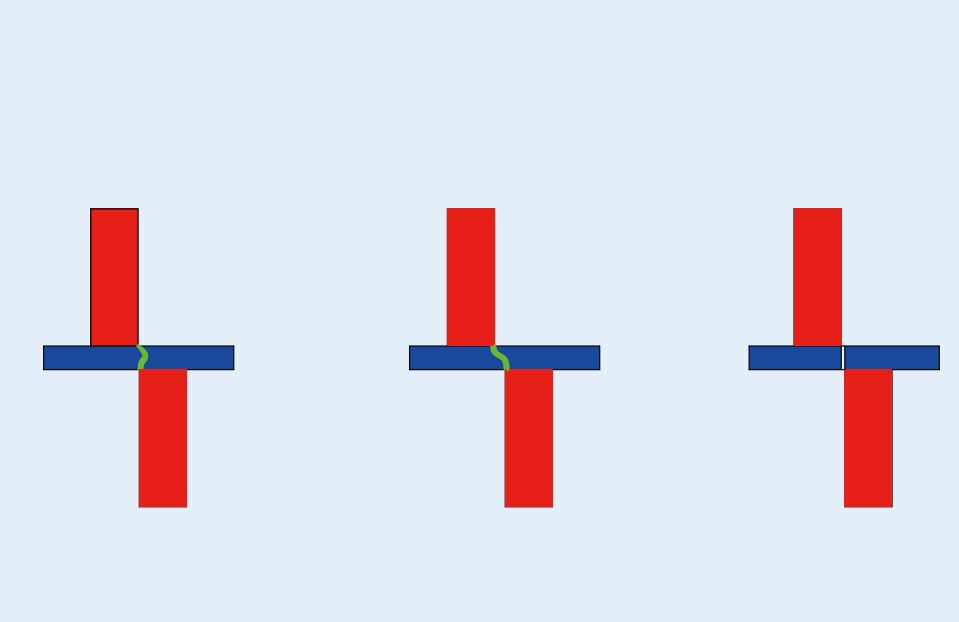

Adjustable cutting clearance |

|

Appropriate adjustment for blade gap will affect the quality of sheet and life of blade; reasonable blade clearance should be choosed according to workpiece material to obtine high quality cutting cross section. |

|

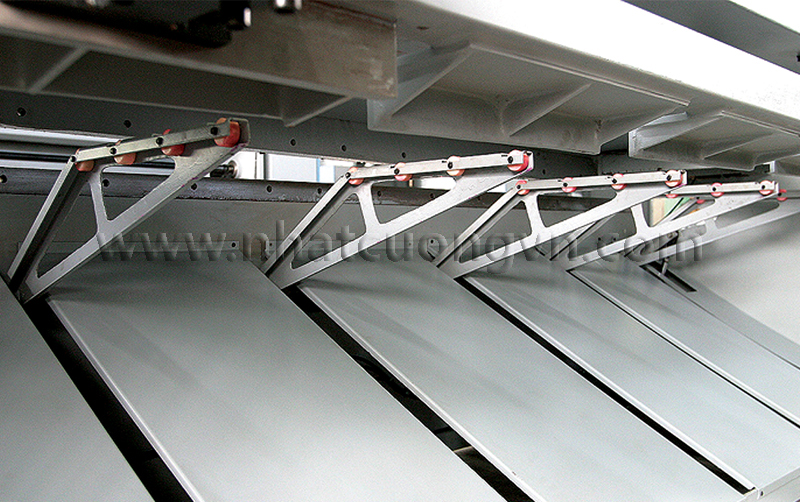

Rear discharging device (option)

- Sheet metal is outputing under the machine, provide safe working environment for operators

- Adopt polyurethane conveyor belt, reduce the surface scratch and noise

- Equip with positioning pneumatic sheet support, convenient for plate positioning, ensure cutting accuracy

- Equip with food wheel, can be easily removed to facilitate the maintenance of the machine

- Equip with small machine (smaller than 8x4050)

|

Thickness |

6 |

|||||

|

Parameter |

Unit |

LGSK-6x2500* |

LGSK-6x3050* |

LGSK-6x4050* |

LGSK-6x5000 |

LGSK-6x6100 |

|

Max cutting thickness |

mm |

6 |

6 |

6 |

6 |

6 |

|

Max cutting length |

mm |

2500 |

3050 |

4050 |

5000 |

6100 |

|

Max shear angle |

° |

0.5-2 |

0.5-2 |

0.5-2 |

0.5-2 |

0.5-2 |

|

Clamps |

14 |

17 |

22 |

24 |

27 |

|

|

Stroks (no load) |

Min |

18 |

16 |

14 |

12 |

10 |

|

Back gauge range |

mm |

10-1000 |

10-1000 |

10-1000 |

10-1000 |

10-1000 |

|

Power of motor |

kW |

7.5 |

7.5 |

7.5 |

15 |

15 |

|

Tank volume |

L |

250 |

250 |

250 |

650 |

650 |

|

Overall dimension(LxWxH) |

mm |

3110x1970x2050 |

3670x1970x2050 |

4670x2070x2180 |

5720x2400x2500 |

6860x2500x2630 |

|

Weight |

kg |

5500 |

6300 |

9000 |

14500 |

20300 |

|

Optional parts |

|

|

|

Special length of front beam |

|

Longer front beam than standard length, can be made according to customer’s requirement, convenient to cut bigger sheet plate |

|

|

|

Angle protractor positioning device |

|

Assemble in the left side of front beam, convenient to cut sheet plate with angle Move along front beam slot front and rear and position at any place, guarantee the precise cutting angle |

|

|

|

Backguage |

|

Rear backguage according to state safety standard, can equip with different standard of photoelectric switch, protect workers who go inside the dangerous rear side of machine |

|

|

Pneumatic support |

||

|

|

Positioning pneumatic sheet support (standard configuration for shear which is smaller than 8x4050) |

|

|

|

First step: Positioning |

|

|

|

Second step: falling sheet |

|

|

|

Combined pneumatic sheet support (option) |

|

|

|

Step one: positioning |

|

|

|

Step two: shearing |

|

|

|

Step three: falling sheet |

|

|

Standard configuration |

|

|

|

Worktable with ball |

|

Worktable with ball to decrease the friction when feeding and the scratch of sheet plate |

|

|

|

Hydraulic system |

|

Adopt integrated hydraulic system from Roxroth, return by accumulator, low temperture, insure stable and reliable performance. |

|

|

|

CNC controller |

|

HGSK CNC machine: Delem DAC360 from Netherland HGS conventional machine: ESTUN E21S from Nanjing |

|

_crop_Yawei_HGS.jpg)

_crop_HSS-YAWEI_logo.jpg)

_crop_front_feeding_2.jpg)

_crop_front_feeding_heavy_1.jpg)