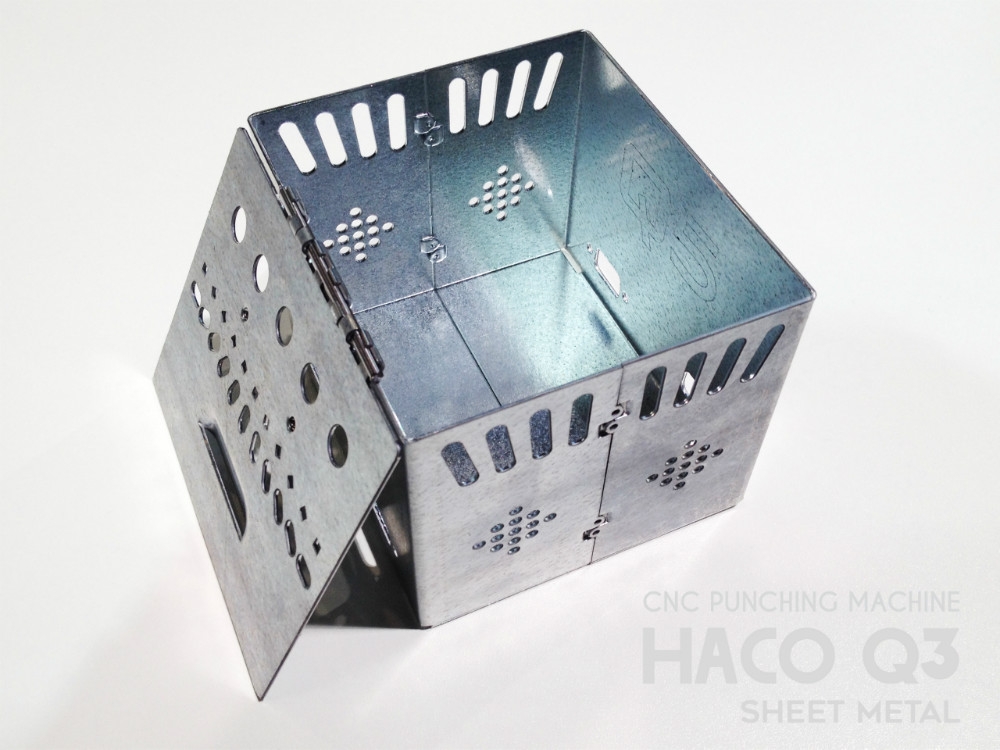

HACO Q3 - CNC Punching Machine

|

|

|

|

Q3 2022-12i / Q3 2030-12i |

|

General |

Capacity in ton |

22 / 30 |

|

Maximum plate thickness |

6.5 mm |

|

|

Number of indexable tools |

12 - 120 |

|

|

|

Punching mechanism |

Hybrid servo electro-hydraulic |

|

CNC control |

TPC 845 Graphics |

|

|

|

22" Full HD touch screen |

|

|

Tool concept |

maximum tool diameter |

Trumpf* style (76.4mm) |

|

Stripperplates |

Standard |

Trumpf* style steel strippers |

|

Optional |

Urithane strippers (2-4-1 style) |

|

|

Hitrates (depending on meterial |

Punching/nibbling |

max. 1200 hpm |

|

Axes strokes |

X-Axis |

2032 mm (80") |

|

Y-Axis |

1600 mm (63") |

|

|

C1-C2-Axis |

360° |

|

|

Z-Axis |

37 mm (1,456") |

|

|

Axes speeds (depending on |

X-Axis |

80 m/min |

|

Y1-Y2-Axis |

80 m/min |

|

|

Traverse speed |

113 m/min |

|

|

Rotation time |

C1-C2-Axis |

122ms/90° tool rotaion |

|

Max. Accelerations |

X-Axis |

1,53 G |

|

Y1-Y2-Axis |

1,53 G |

|

|

C-Axes |

1256 rev/s2 |

|

|

Sheet dimensions |

X-Axis |

2032 mm (80") |

|

Y-Axis |

1600 mm (63") |

|

|

Max-sheet weight |

150 kh |

|

|

Programming accuracies |

X-Y Axis |

0,01 mm |

|

Positioning accuracies - per meter |

X-Y Axis |

± 0,1 mm |

|

Futher machine specifications |

Weight |

11000kg |

|

Dimensions (WxLxH) |

4080x5310x2270 |

_crop_HACO_Q3_2022-20_2018_with_cabinet_1080_resize.jpg)

_crop_Q3.jpg)

_crop_Bending_part_1.jpg)

_crop_Bending_part_2.jpg)

_crop_HACO_Q5_1_1.jpg)