HACO - Pressmaster

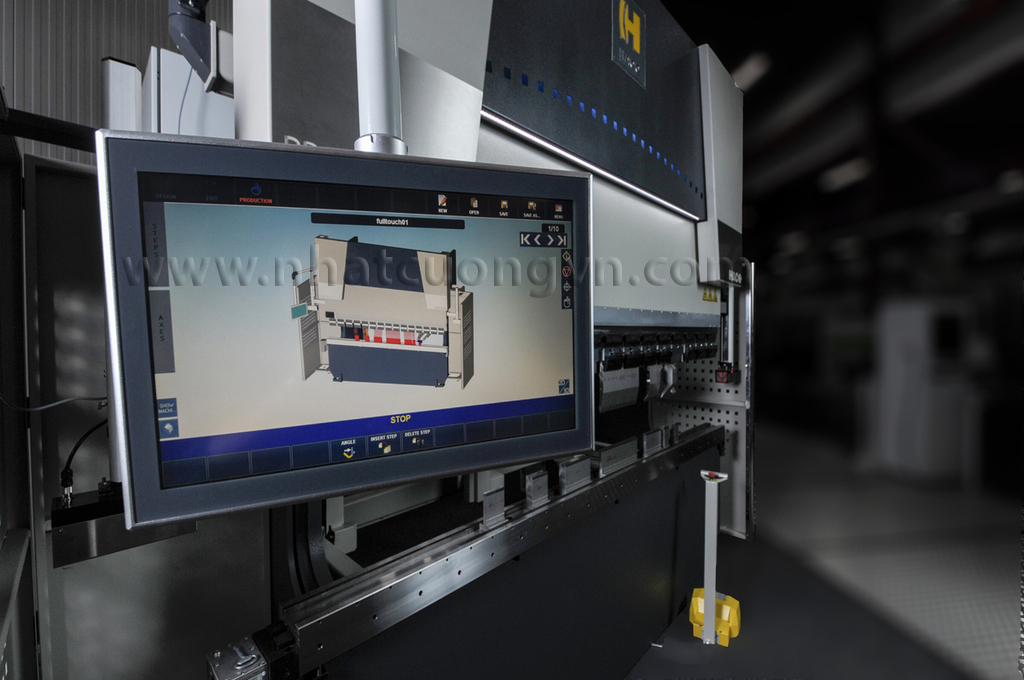

Pressmaster: The Pressmaster is a more-axes CNC pressbrake with electronically controlled beam parallelism and depth-stop setting.

Special features:

SyncView was invented from the notion that it would be ideal to be able to watch both screen and the workpiece simultaneously during the bending process. This innovative solution consists of a tablet screen that is automatically positioned at the optimal location: where the piece is actually being worked on by the operator.

Product description:

The combination of our 2D/3D-graphic CNC control with automatic generation of the bending program, our backgauge system and theincreased daylight opening makes the PRESSMASTER the most versatile press brake on the market.

|

Type |

PRESSMASTER |

20075 |

30075 |

40100 |

|

Bending length |

A |

2100 mm |

3100 mm |

4100 mm |

|

Capacity |

|

750 kN |

750 kN |

1000 kN |

|

Distance between housings |

B |

1600 mm |

2600 mm |

3150 mm |

|

Gap |

C |

400 mm |

400 mm |

400 mm |

|

Daylight Opening |

D |

570 mm |

570 mm |

570 mm |

|

Daylight Opening |

D |

540 mm |

540 mm |

540 mm |

|

Stroke |

E |

370 mm |

370 mm |

370 mm |

|

Table height |

G |

840 mm |

840 mm |

915 mm |

|

Fast approach speed |

|

200 mm/s |

200 mm/s |

200 mm/s |

|

Max. bending speed |

|

10 mm/s |

10 mm/s |

10 mm/s |

|

Fast return speed |

|

170 mm/s |

170 mm/s |

170 mm/s |

|

Motor power |

|

7.5 kW |

7.5 kW |

11 kW |

|

Demention (LxWxH) |

H/I/J |

2450x1850x3250 |

3500x1850x3250 |

4400x2050x3250 |

|

Weight |

|

5600 kg |

6400 kg |

11000 kg |

Standard Equipment:

- FastBEND-2D Premium Graphic Control with 15” Touch Screen

- Increased daylight opening (up to 620 mm and 2500 kN models)

- Fast X-R-Z1/Z2 Backgauge

- Fast Approach Speed 200 mm/s (models up to 2000kN)

- Fast Return Speed 170 mm/s (models up to 2000kN)

- Stroke X-axis = 800mm, speed = 1000mm/s (models up to 4m and 2500kN)

- Stroke R-axis = 130mm (models up to 4m and 2500kN)

- Z1-Z2 axis , speed = 1000mm/s (models up to 4m and 2500kN)

- Manual Adjustable Crowning Table for European Standard tooling

- 2 Movable sheet supports

- European Standard toptooling with Quick Manual Clamping arrangement

Options:

- HacoBend-2D/3D Offline Software

- 5 and 6 axes backgauge systems

- Angle Measurement System ALFA/F and AST (= Angle Sensor Tool)

- New Standard tooling (Wila / Wila Premium / LED Tool indicator)

- CNC sheet following system

- Optical Guarding systems (Lazersafe LZS-005, Fiessler AKAS III, …)

- SyncView

_crop_may-chan-thep-tam.jpg)

_crop_HACO_Hydraulic_PressBreake_PPM_14.jpg)

_crop_Haco_Euromaster_E_5.jpg)

_crop_may-chan-thep-tam.jpg)